Smart Factories – Connected Learning

Establishing an innovative learning system for smart production and operational methods

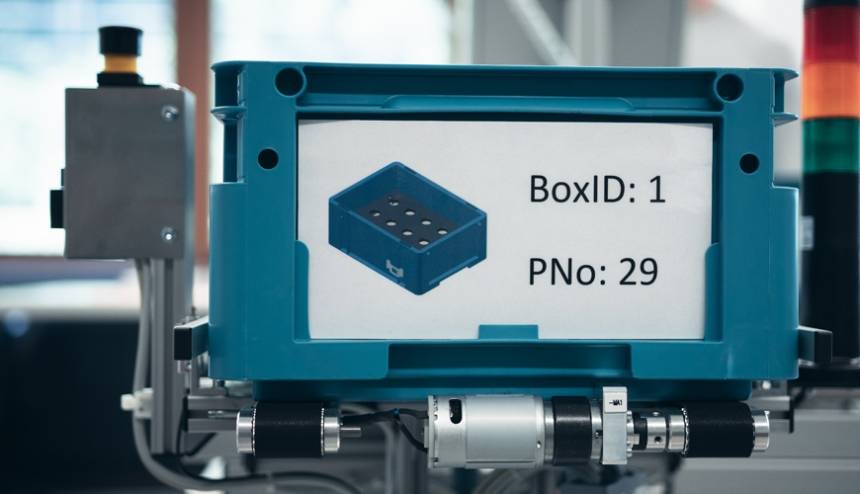

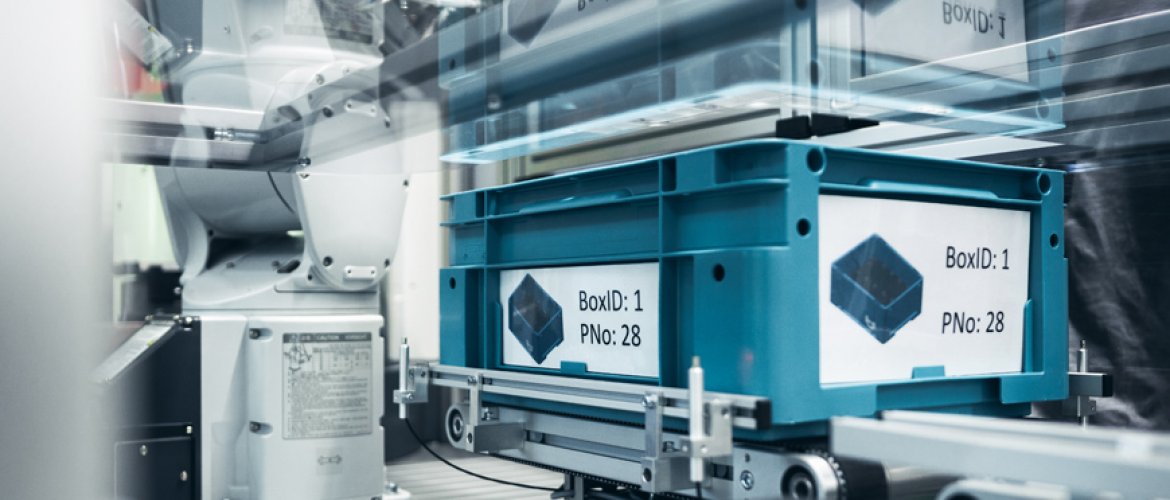

This project creates a network of business and different educational institutions in order to establish an innovative learning system for smart production and operational methods. Thanks to the integrative conception, a significant added value is achieved. This education and training project for digital transformation is unique in this form, certainly within Austria. Employing Smart Factories and Cyber-Physical Systems (CPSs), issues related to Industry 4.0 can be visualized, simulated, and trained. Technical, methodological, social, and self-organization skills can be learned efficiently. Thanks to an integrative cloud solution, sites can be networked and shared to achieve complex tasks without additional investments. This creates a true economic system.

Prototype development & industrial implementation

At the three separate locations, viz. the University of Applied Sciences Kufstein Tirol (UAS), the Tyrolean Vocational School for Business and Technology Kufstein-Rotholz (TVSBT), and at the company STIHL Tirol GmbH, Smart Factories were set up as part of the project. In production laboratories with state-of-the-art equipment, the respective core tasks of the institutions can be learned by means of highly up-to-date hardware and software. At the UAS, the first step is the prototype development of Industry 4.0 solutions. These are transformed into an initial practical concept in an industry-like manufacturing laboratory at the TVSBT. This ultimately results in an industrial implementation for the business partner. Thanks to a secure cloud solution provided by Kufgem GmbH Kufstein, a reliable data transfer between the individual interfaces can be achieved. A grant of EUR 510,000 was provided by the State of Tyrol as part of its digitization campaign and a further grant of EUR 200,000 came from the two project partners STIHL and Kufgem.